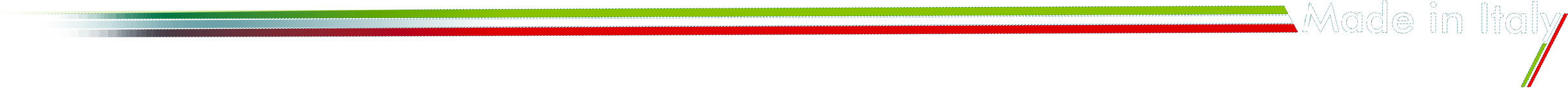

Type A

The Type A range, made of iron, was developed in the 1960s and is equipped with a safety system. It is used for transporting various substances such as sewage, sludge, dust, granular materials, and finds applications in irrigation, road construction, drainage, and civil projects.

Procedure for assembling Type A spherical

couplings with diameters from 150 to 250

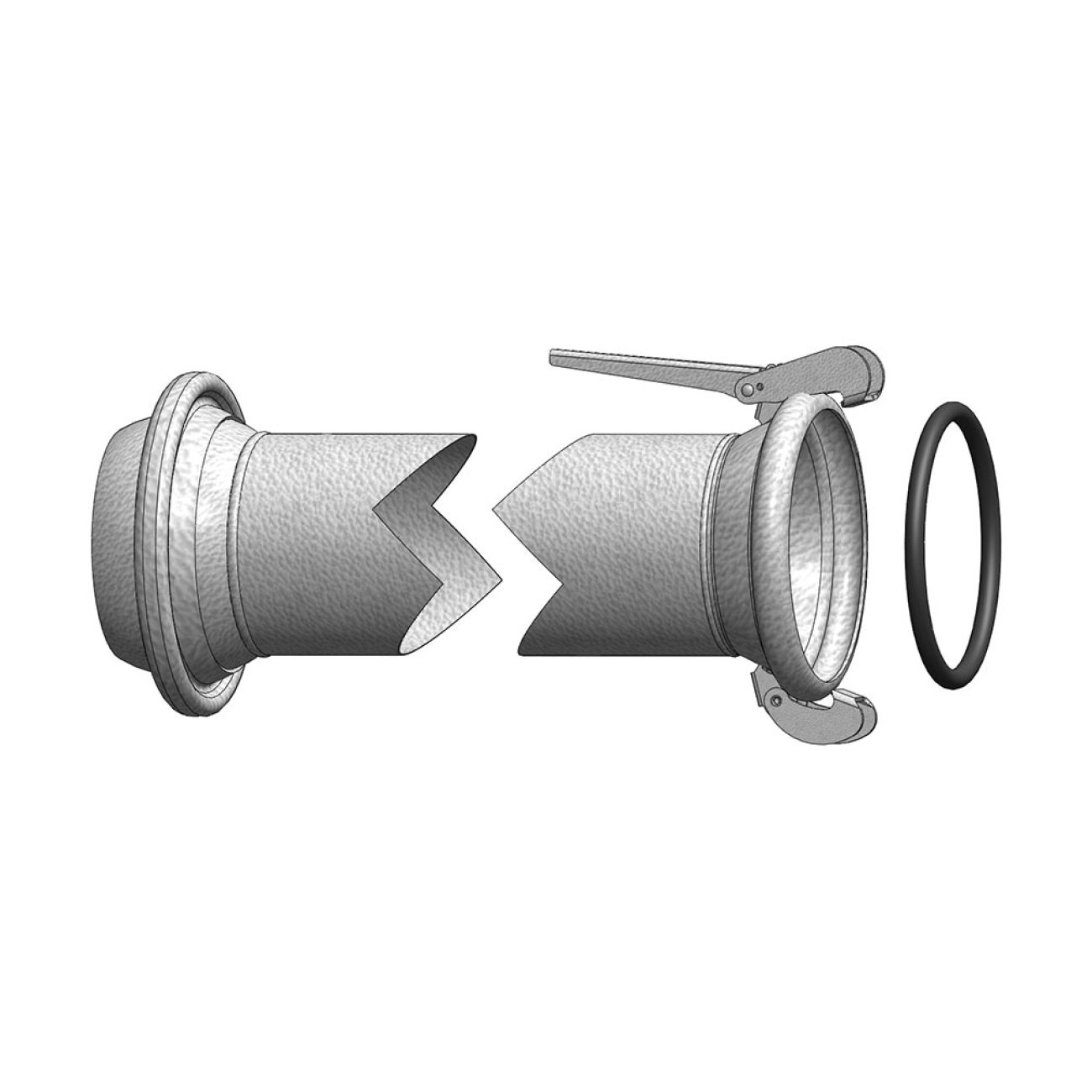

Position the male coupling against the gasket housed inside the female coupling.

Position the male coupling against the gasket housed inside the female coupling. Position the short hook in the outer seat of the ring.

Position the short hook in the outer seat of the ring. While holding the short hook in the outer seat of the ring, open the handle so that the long hook positions itself in the outer seat of the ring.

While holding the short hook in the outer seat of the ring, open the handle so that the long hook positions itself in the outer seat of the ring. Finally, once ensuring that the male coupling is sufficiently aligned and does not risk damaging the gasket, close the handle to tighten the complete coupling.

Finally, once ensuring that the male coupling is sufficiently aligned and does not risk damaging the gasket, close the handle to tighten the complete coupling. Procedure for assembling Type A spherical

couplings with diameters from 300 to 400

Position the male coupling against the gasket housed inside the female coupling.

Position the male coupling against the gasket housed inside the female coupling. Position the short hook in the outer seat of the ring.

Position the short hook in the outer seat of the ring. While holding the short hook in the outer seat of the ring, open the handle lever so that the long hook positions itself in the outer seat of the ring.

While holding the short hook in the outer seat of the ring, open the handle lever so that the long hook positions itself in the outer seat of the ring. Finally, once ensuring that the male coupling is sufficiently aligned and does not risk damaging the gasket, insert the handle into the lever to tighten the complete coupling.

Finally, once ensuring that the male coupling is sufficiently aligned and does not risk damaging the gasket, insert the handle into the lever to tighten the complete coupling.