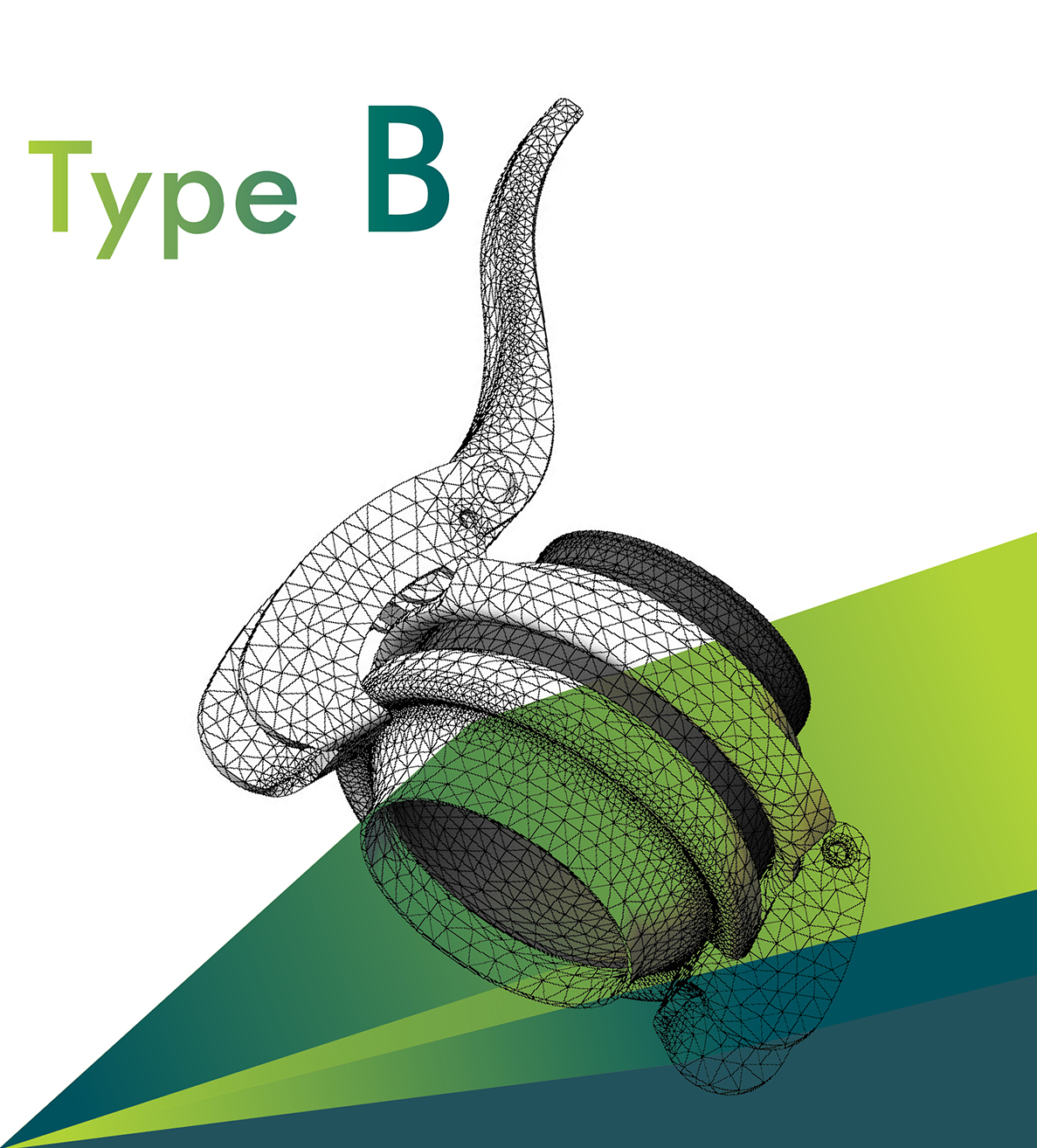

Type B

The Type B range originated in the 1970s-80s and is fully interchangeable with the Bauer coupling. Currently, it is made of iron, stainless steel, and aluminum and is normally supplied in the version with a safety system. It is used for a wide variety of applications such as irrigation, road construction, drainage, civil projects, bypass lines, in the food sector and in the chemical industry. The Type B coupling is widespread throughout the world.

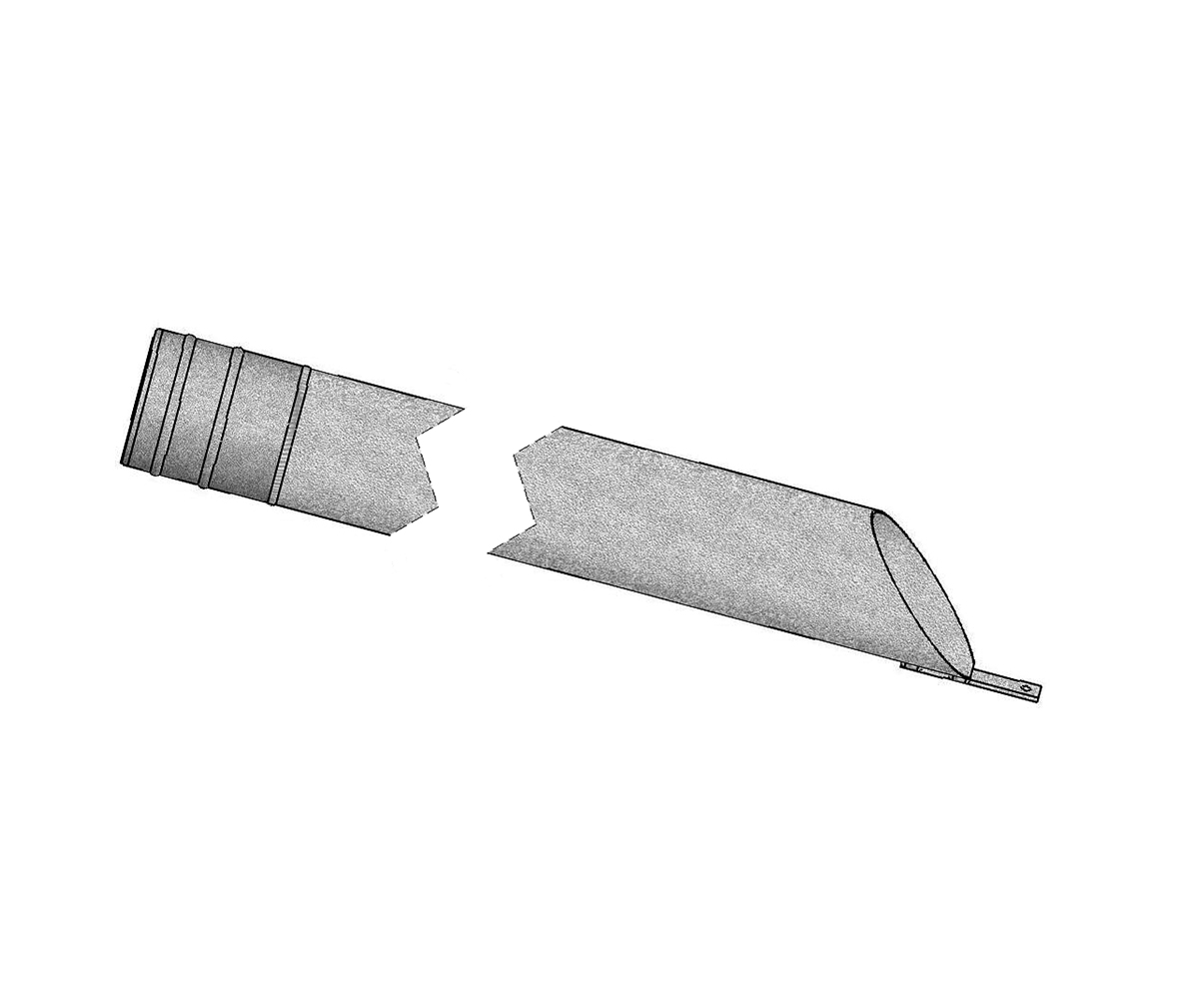

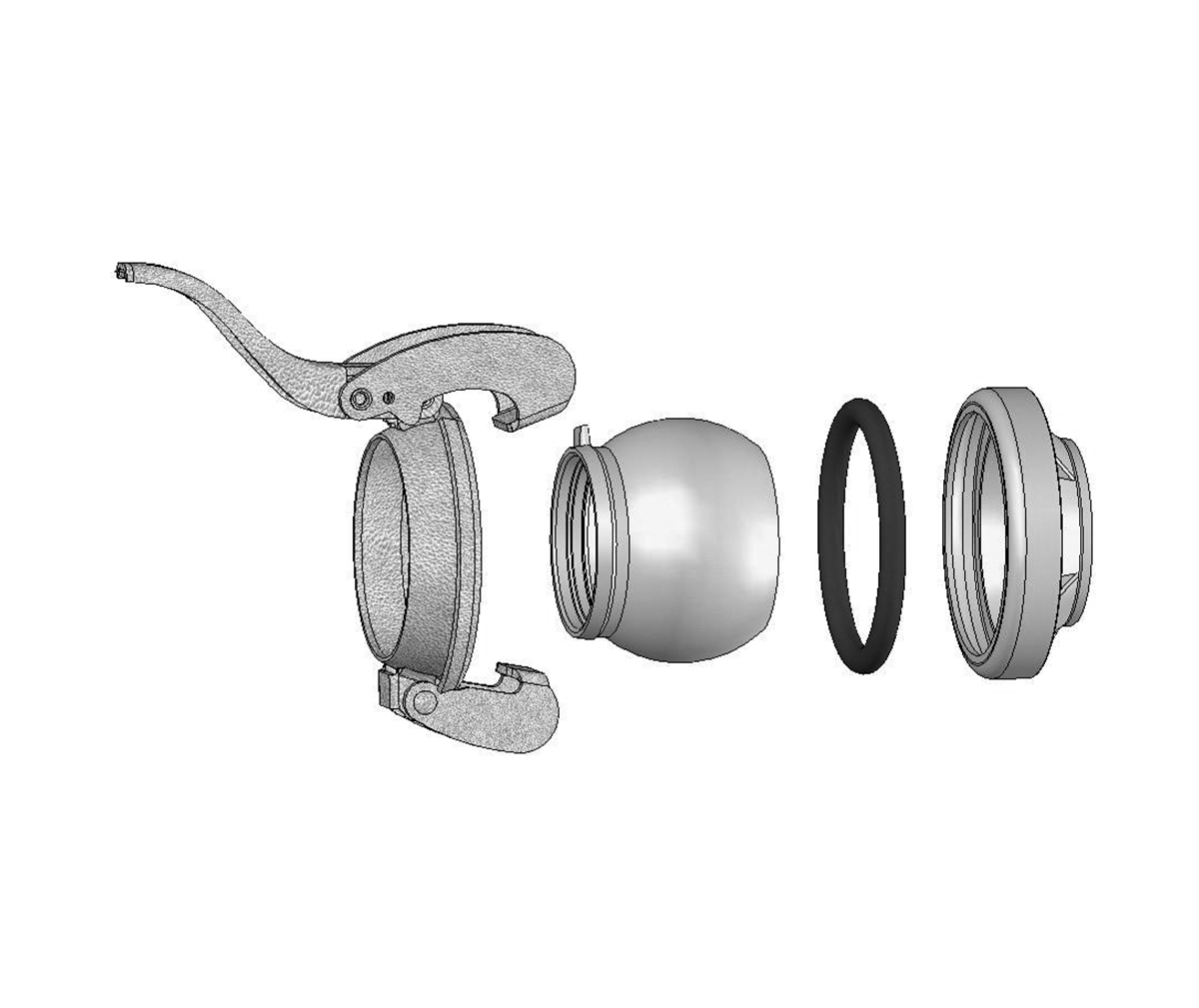

Procedure for assembling Type B spherical

couplings from diameter 50 to diameter 194

Position the male coupling against the gasket housed inside the female coupling.

Position the male coupling against the gasket housed inside the female coupling. Position the short hook in the outer seat of the female.

Position the short hook in the outer seat of the female. While holding the short hook in position in the outer seat of the female, open the handle so that the long hook is positioned in the outer seat of the female coupling.

While holding the short hook in position in the outer seat of the female, open the handle so that the long hook is positioned in the outer seat of the female coupling. Finally, once it is ensured that the male coupling is sufficiently aligned and there is no risk of damaging the gasket, close the handle to tighten the complete coupling.

Finally, once it is ensured that the male coupling is sufficiently aligned and there is no risk of damaging the gasket, close the handle to tighten the complete coupling. Procedure for assembling Type B spherical

couplings from diameter 250 to diameter 450

Position the male coupling against the gasket housed inside the female coupling.

Position the male coupling against the gasket housed inside the female coupling. Position the short hook in the outer seat of the female.

Position the short hook in the outer seat of the female. While holding the short hook in position in the outer seat of the female, open the handle so that the long hook is positioned in the outer seat of the female coupling.

While holding the short hook in position in the outer seat of the female, open the handle so that the long hook is positioned in the outer seat of the female coupling. Finally, once it is ensured that the male coupling is sufficiently aligned and there is no risk of damaging the gasket, close the handle to tighten the complete coupling.

Finally, once it is ensured that the male coupling is sufficiently aligned and there is no risk of damaging the gasket, close the handle to tighten the complete coupling.