Type D

The first Dallai coupling was created in 1959 and is fully interchangeable with all similar couplings produced in Italy. The Type D range is made of iron, stainless steel and aluminum, and depending on requirements, a version with a safety lock can be supplied. It is mainly used in the field of irrigation and for various applications such as drainage, sewage transport, road construction, in the food sector and in the chemical industry.

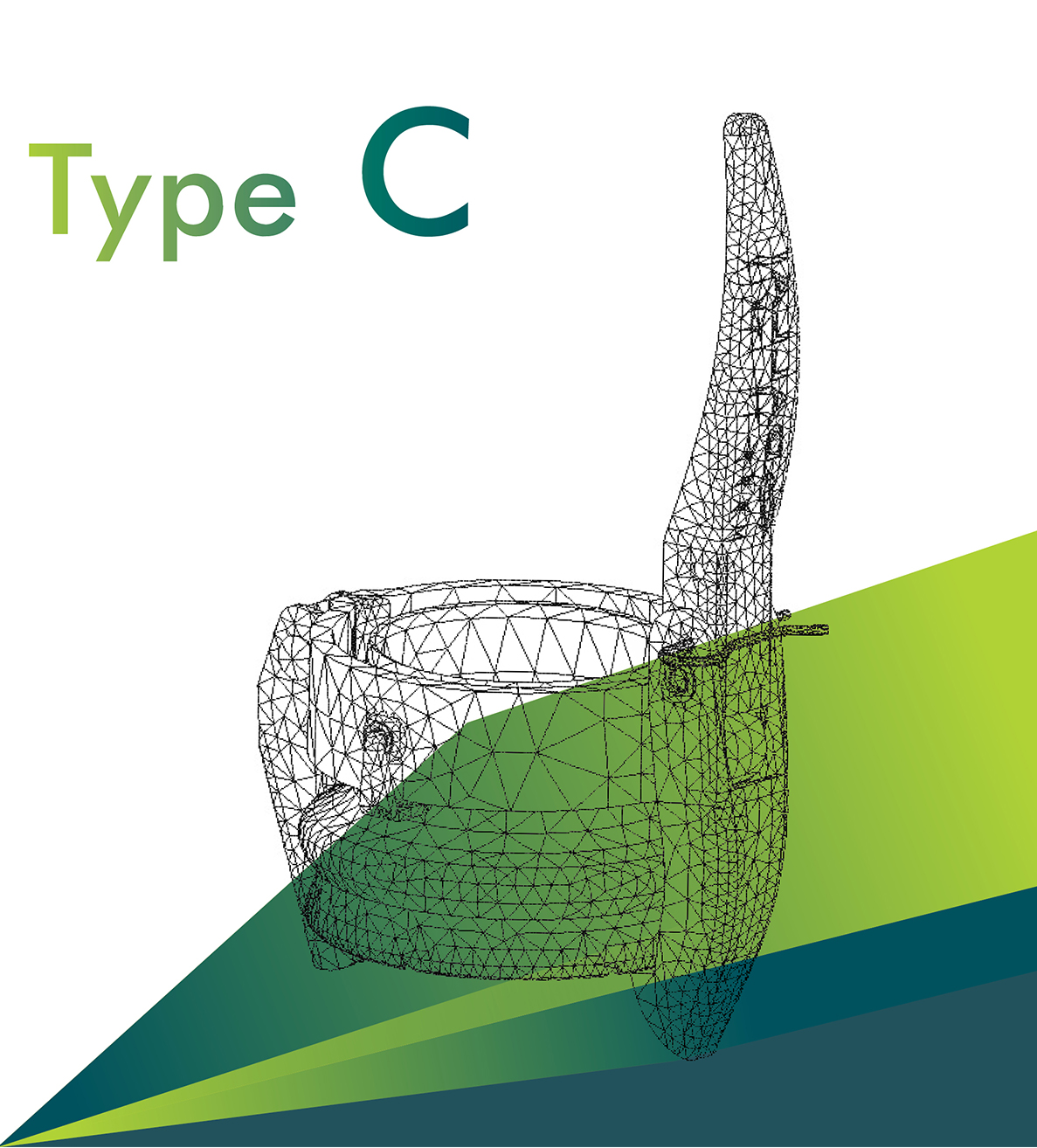

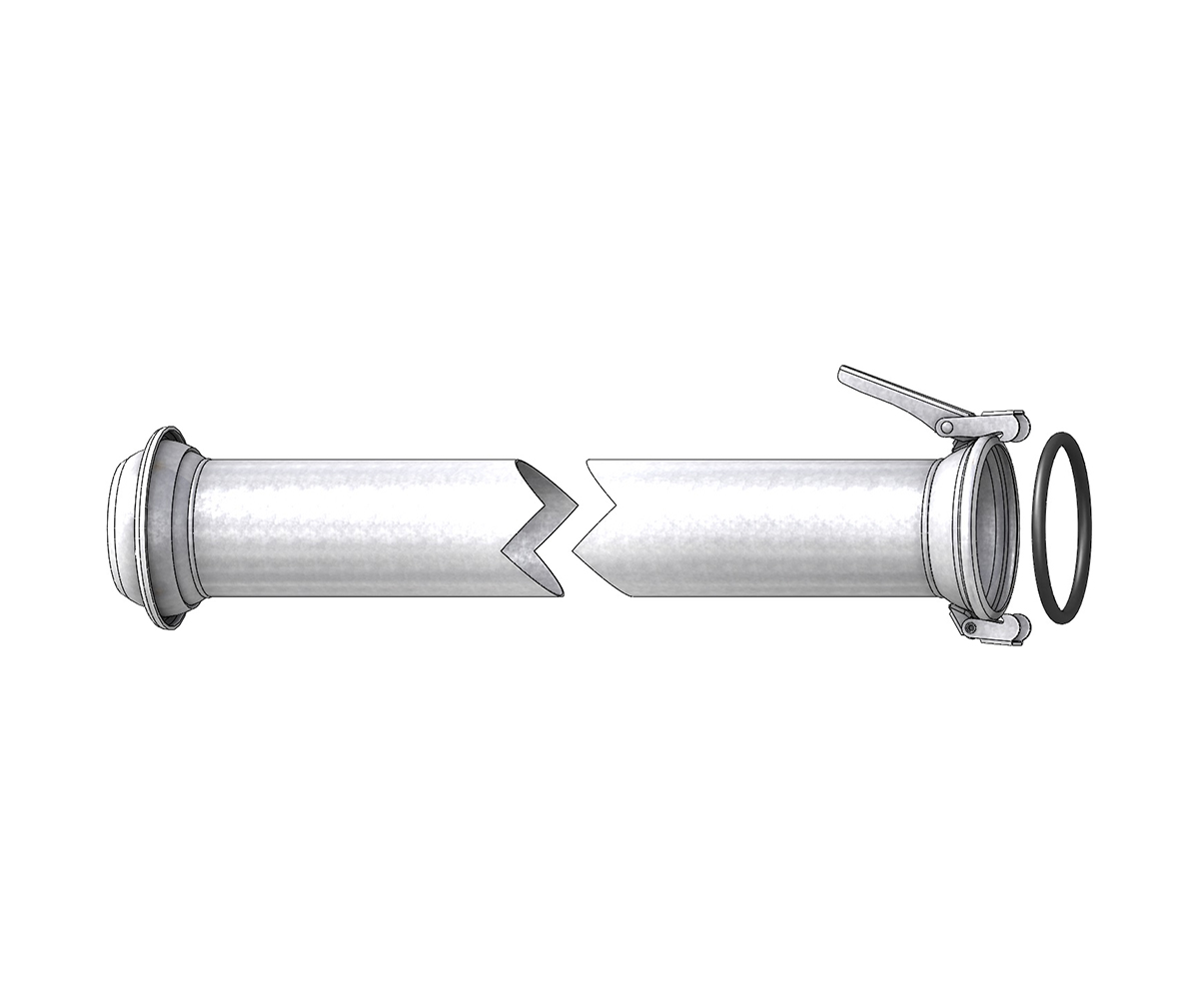

Procedure for assembling Type D spherical couplings.

Position the male coupling against the gasket housed inside the female coupling.

Position the short hook in the outer seat of the ring.

While holding the short hook in position in the outer seat of the ring, open the handle so that the long hook is positioned in the outer seat of the ring.

While holding the short hook in position in the outer seat of the ring, open the handle so that the long hook is positioned in the outer seat of the ring. Finally, once it is ensured that the male coupling is sufficiently aligned and there is no risk of damaging the gasket, close the handle to tighten the complete coupling.

Finally, once it is ensured that the male coupling is sufficiently aligned and there is no risk of damaging the gasket, close the handle to tighten the complete coupling.Technical advice

For total safety against accidental opening, insert the cotter pin into the appropriate holes if present in the handle and long hook.

For new couplings, in order to close them more easily, it is advisable (especially for larger sizes) to lightly lubricate the gasket with a suitable lubricant.

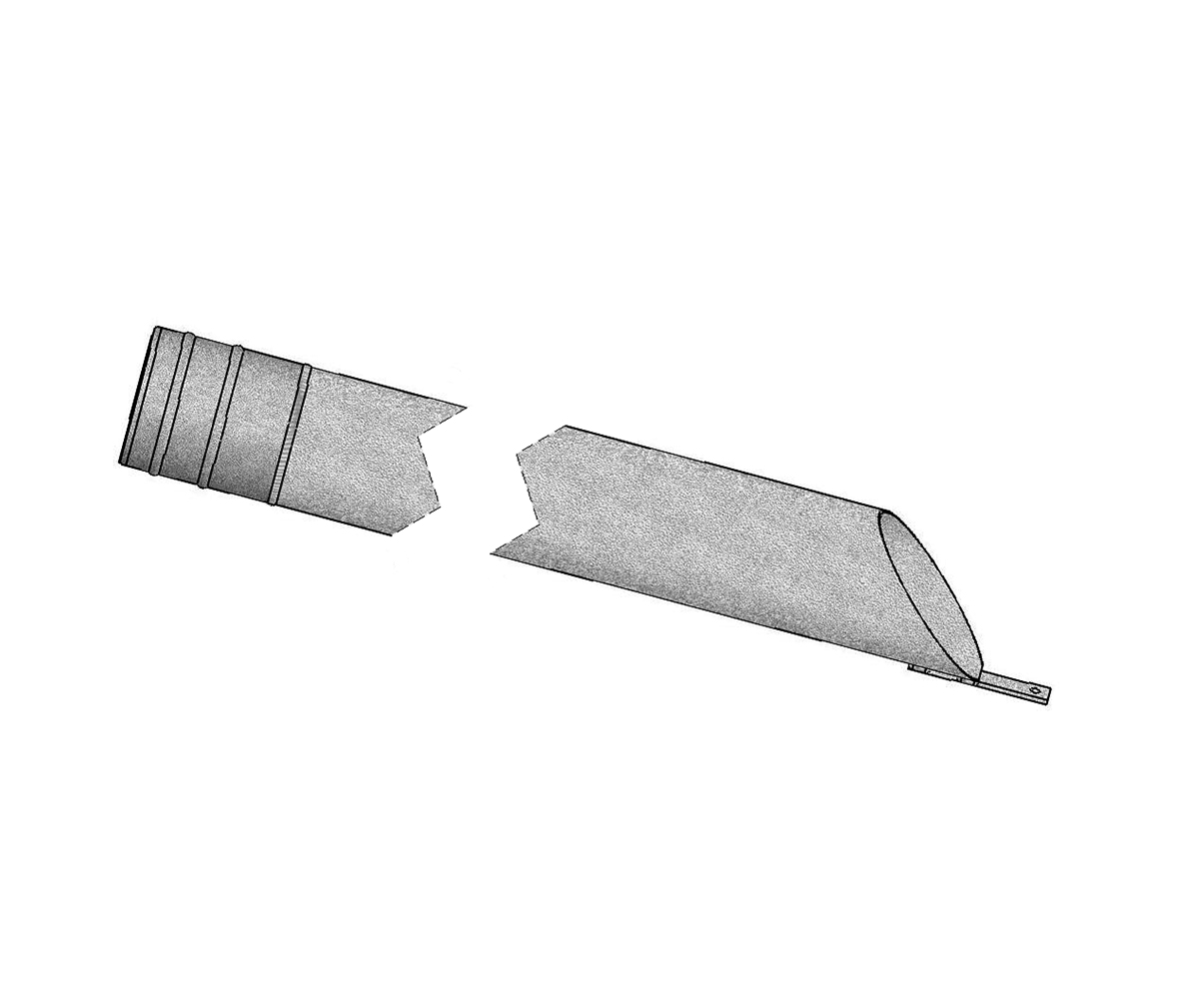

Materials

Steel couplings are mainly produced in S235JR UNI EN ISO 10025-2005 (EX Fe360B UNI EN ISO 10025-1995).

Stainless steel couplings are made of X5CrNi18-10 UNI EN 10088 (AISI304).

Products, where specified, are supplied with Hot Dip Galvanizing coating according to UNI EN ISO 1461 standards.